News

How to Use Ethyl Acetate Effectively in Your Projects and Applications

In the realm of organic solvents, Ethyl Acetate stands out for its versatility and effectiveness across various industries, from pharmaceuticals to food processing. Dr. Emily Chen, a noted expert in chemical engineering, emphasizes the importance of this solvent, stating, "Ethyl Acetate is not only an efficient solvent, but its low toxicity and pleasant odor make it a favorable choice for countless applications." This highlights the significant role that Ethyl Acetate plays in enhancing both the productivity and safety of various projects.

As more industries recognize the potential of Ethyl Acetate, understanding how to utilize it effectively becomes essential. Whether you are involved in extraction processes, as a cleaning agent, or in the formulation of consumer products, knowledge of Ethyl Acetate’s properties and applications can lead to improved outcomes. The following sections will provide insights into best practices, safety measures, and innovative uses of Ethyl Acetate, ensuring that your projects benefit from this remarkable solvent's attributes. From its role in the laboratory to its application in manufacturing, Ethyl Acetate is an indispensable tool for modern chemists and engineers.

Understanding Ethyl Acetate: Properties and Characteristics

Ethyl acetate is a colorless, volatile liquid widely recognized for its pleasant, sweet aroma, resembling that of pear drops. Its chemical formula is C4H8O2, and it is classified as an ester, making it an efficient solvent in a variety of applications, particularly within the paint and coatings industry. According to a report by Research and Markets, the ethyl acetate market size was valued at approximately $1.5 billion in 2021 and is projected to grow significantly, driven by increasing demand in the automotive, electronics, and food sectors. The low toxicity and high evaporation rate of ethyl acetate make it a preferred choice for applications requiring rapid drying times.

In addition to its solvent properties, ethyl acetate exhibits excellent biodegradability, which enhances its appeal in environmentally friendly applications. Studies show that ethyl acetate's volatility allows it to evaporate quickly, reducing solvent waste and promoting better working conditions by minimizing exposure risks. The flash point of ethyl acetate is approximately 24°C, categorizing it as a flammable substance; therefore, proper handling and storage protocols are crucial. Furthermore, its compatibility with various resins and polymers makes ethyl acetate an essential component in formulating adhesives and inks, contributing to its versatile applications across multiple industries.

How to Use Ethyl Acetate Effectively in Your Projects and Applications

| Property | Value |

|---|---|

| Chemical Formula | C4H8O2 |

| Molecular Weight | 88.11 g/mol |

| Boiling Point | 77.1 °C |

| Density | 0.897 g/cm³ |

| Solubility in Water | Moderately soluble |

| Flash Point | -4 °C |

| Applications | Solvent for coatings, adhesives, and pharmaceuticals |

| Safety Precautions | Use in well-ventilated areas, avoid open flames |

Common Uses of Ethyl Acetate in Various Industries

Ethyl acetate is a versatile solvent widely used across various industries due to its effective properties. In the food industry, it serves as a flavoring agent, providing fruity and sweet notes that enhance the taste of products such as baked goods, candies, and beverages. Its natural occurrence in fruits makes it a safe choice, adhering to food safety standards while adding a pleasant aroma and flavor.

In the realm of coatings and adhesives, ethyl acetate is favored for its ability to dissolve various resins and polymers. It's commonly used in the production of paints, varnishes, and sealants, facilitating smooth application and rapid drying times. This characteristic proves beneficial in increasing production efficiency in manufacturing settings.

**Tips:** When using ethyl acetate, consider using it in a well-ventilated area, as its vapors can be harmful in concentrated forms. Always wear appropriate protective gear to minimize skin and respiratory exposure. Additionally, when mixing it with other chemicals, perform a small test to ensure compatibility and desired outcomes without unwanted reactions.

Common Uses of Ethyl Acetate in Various Industries

Safety Precautions When Handling Ethyl Acetate

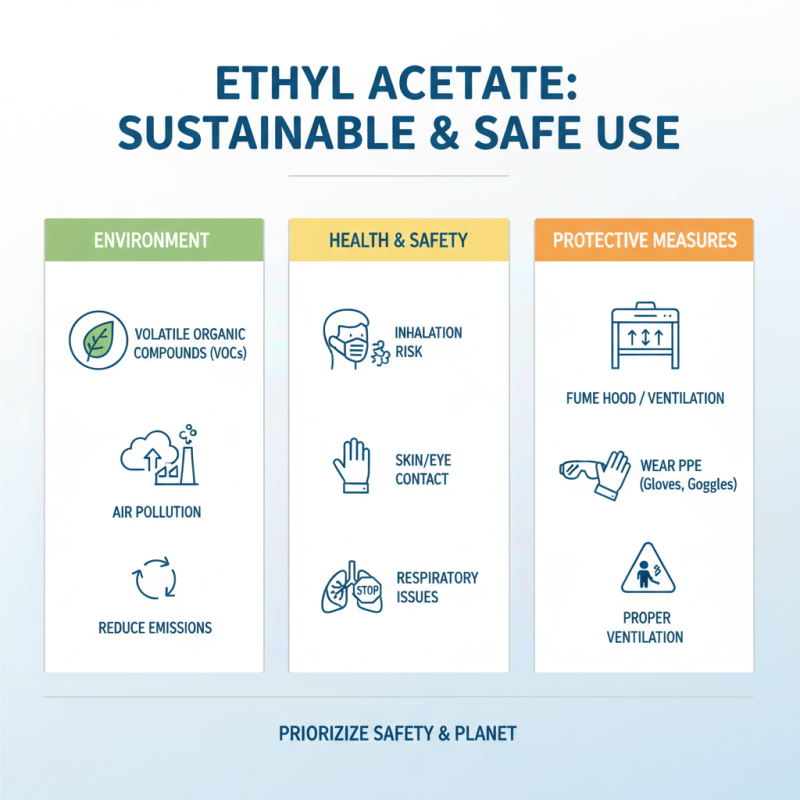

Ethyl acetate is widely utilized in various industries due to its effective solvent properties, particularly in the formulation of paints, coatings, and adhesives. However, handling this chemical requires strict adherence to safety precautions to mitigate potential risks. According to the National Institute for Occupational Safety and Health (NIOSH), exposure to ethyl acetate can lead to respiratory irritation, headaches, or even loss of consciousness in severe cases if proper safety measures are not taken. It is paramount for workers to be informed about the risks and to implement measures such as using masks or respirators when working in enclosed spaces.

In addition to personal protective equipment (PPE), adequate ventilation is crucial when using ethyl acetate. The American Conference of Governmental Industrial Hygienists (ACGIH) recommends ensuring that workplaces have ventilation systems that effectively dilute airborne concentrations of chemicals. Furthermore, it is essential to store ethyl acetate in appropriate containers and away from sources of ignition to minimize the risk of fire or explosion. Regular safety training and updates on handling procedures can significantly reduce accidents and potential health risks associated with this volatile solvent. By prioritizing safety, industries can harness the benefits of ethyl acetate while safeguarding the health of their workers.

The proper usage and handling of ethyl acetate can enhance work efficiency while maintaining a safe environment. Remember to always follow the recommended guidelines and utilize adequate PPE to reduce any health risks.

Effective Techniques for Ethyl Acetate Application in Projects

Ethyl acetate is a versatile solvent widely used in various projects due to its effectiveness and relatively low toxicity. To utilize ethyl acetate effectively, it’s essential to consider its properties and optimal application techniques. One effective method is to employ it as a solvent for extraction processes, especially in the food and cosmetic industries. By carefully monitoring temperature and duration during extraction, one can ensure that desired compounds are efficiently separated while preserving their integrity.

Another important technique for applying ethyl acetate is in the cleaning and degreasing of surfaces before further processing or assembly. Its ability to dissolve oils and residues makes it an ideal choice for preparing materials in industries such as electronics or manufacturing. Utilizing ethyl acetate in these applications also involves ensuring good ventilation and wearing appropriate safety gear to handle vapors safely. By integrating these techniques, one can maximize the benefits of ethyl acetate in various projects, enhancing both the efficiency and quality of outcomes.

Environmental Considerations and Disposal of Ethyl Acetate

Ethyl acetate is a widely used solvent in various industries, but its environmental considerations are crucial for sustainable practices. When working with ethyl acetate, it is important to recognize its volatile organic compounds (VOCs), which can contribute to air pollution and have potential harmful effects on human health. Therefore, proper ventilation is essential in any workplace where ethyl acetate is utilized. Ideally, projects should be conducted in fume hoods or well-ventilated areas to minimize inhalation risks. Additionally, the use of personal protective equipment (PPE) such as gloves and goggles can help mitigate any direct contact with the solvent.

Disposing of ethyl acetate also requires careful consideration to minimize environmental impact. It is important to follow local regulations and guidelines for hazardous waste disposal, as improper disposal can lead to soil and water contamination. Many organizations advocate for recycling solvents whenever possible, which not only helps reduce waste but also conserves resources. In cases where disposal is necessary, ethyl acetate should be collected in designated waste containers and processed by licensed waste disposal facilities. This approach not only aligns with environmental best practices but also helps ensure that projects using ethyl acetate are conducted responsibly and sustainably.

Related Posts

-

Explore Global Demand for Ethyl Acetate at the Successful 137th Canton Fair in Guangzhou

-

Exploring Industry Applications of Best Ethyl Acetate and How to Maximize Its Benefits

-

Exploring Industrial Applications of Best Levulinic Acid: Overcoming Challenges in Biofuel Production

-

Exploring Global Opportunities for Ethyl Oleate at the 2025 Canton Fair: A Rising Trend in International Trade

-

Key Factors to Identify Reliable Manufacturers of Propylene Glycol for Global Buyers

-

Exploring the 2025 Top+ Digital Trends: The Role of Propylene Glycol in the Pharmaceutical and Food Industries